China Clay Graphite Crucible Factory Manufacturer, Supplier, Factory

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Clay Graphite Crucible Factory,Clay Graphite Crucible,High quality Clay Graphite Crucible,Clay Graphite Crucible for Smelting,Clay Graphite Crucible Manufacturer, Our tenet is evident each of the time: to provide good quality solution at competitive rate to clients throughout the planet. We welcome potential purchasers to call us for OEM and ODM orders.

Clay Graphite Crucible Factory, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to give our best service to satisfy all your needs! Remember to contact us right away!

Hot Products

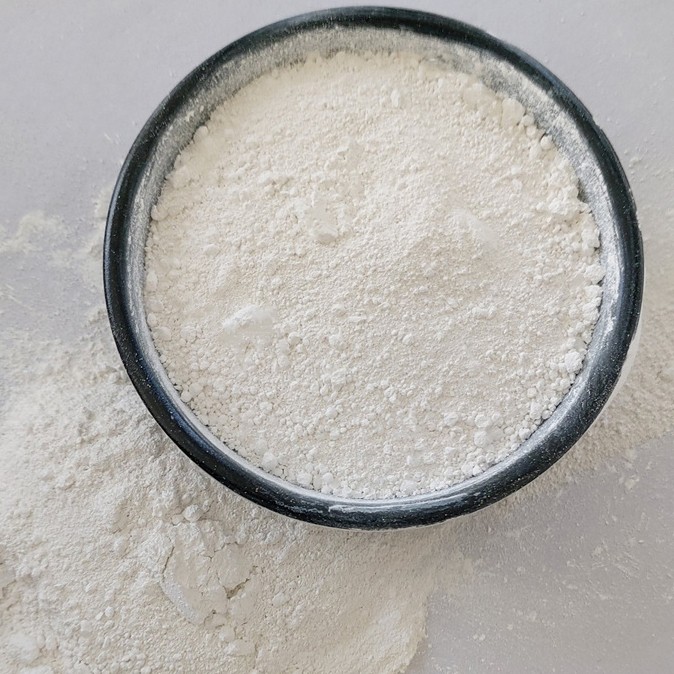

Calcined Aluminum Oxide Powder

Shandong Jiayin New Materials Co., Ltd. is a professional factory and supplier of Calcined aluminum Oxide powder.The Calcined aluminum Oxide powder produced has high purity, low impurities, and uniform particle size distribution; Calcined aluminum Oxide powder after heating treatment to remove crystal water, organic matter, and impurities, is an important industrial raw material widely used in the ceramic industry, coating industry, refractory materials, catalysts, electronics, construction, chemical industry, and other fields..CAS number: 1344-28-1,Purity 98.5-99%.Chlorinated Titanium Dioxide

Chlorinated titanium dioxide is a relatively advanced production method and is currently the main production process in our factory. The chlorinated titanium dioxide powder we produce has significant advantages such as high product purity, uniform particle size distribution, good whiteness, and easy dispersion. The chlorinated titanium dioxide we produce is cheap, with sufficient supply and qualified quality. After exporting to Europe, America, Japan, South Korea, Southeast Asia, and Africa, our products have been widely praised by customers from various countries. CAS No.:13463-67-7.Nano Zinc Oxide

As a high-tech new material enterprise in China, our company independently researches and develops nano zinc oxide, which is a new type of multifunctional fine inorganic material. Due to the relatively small size of nano zinc oxide particles,the electronic structure and crystal structure of the surface of zinc oxide nano changes, resulting in surface effect, volume effect, quantum size effect and macroscopic tunneling effect that macroscopic objects do not have, as well as high transparency, high dispersion, etc. CAS No.: 1314-13-2.Nano Alumina Powder

The nano alumina powder produced by our company is a type of nano scale aluminum oxide with a chemical formula of Al2O3, There are eleven crystals of α, β, γ, δ, η, θ, κ and χ. Has excellent physical and chemical properties, high specific surface area, high porosity, controllable particle size distribution, and good optoelectronic properties. Nano alumina powder still exhibits high strength, toughness, and good stability at high temperatures. CAS:344-28-1, The purity can reach 99.99%.Clay Graphite Crucible

The clay graphite crucible produced by our company adopts a new special coating technology, which can increase the service life of the graphite crucible by nearly twice. It uses high-quality raw materials with guaranteed quality. We can customize processing according to customer needs.High Purity Graphite Powder

Shandong Jiayin New Materials Co., Ltd. is a large manufacturer and supplier of high purity graphite powder in China. The company has established workshops for mineral processing, manufacturing and processing, quality inspection, packaging, and warehousing. It has modern production and testing equipment, advanced manufacturing processes, and produces high purity graphite powder with a carbon content of over 90%-99.99% at a low price and excellent quality.