The main types of titanium dioxide powder

2025-11-09

The main types of titanium dioxide: There are various classification methods for titanium dioxide (titanium dioxide, TiO ₂), and the core differences are reflected in the crystal structure and production process, which directly determine its performance and applicable scenarios.

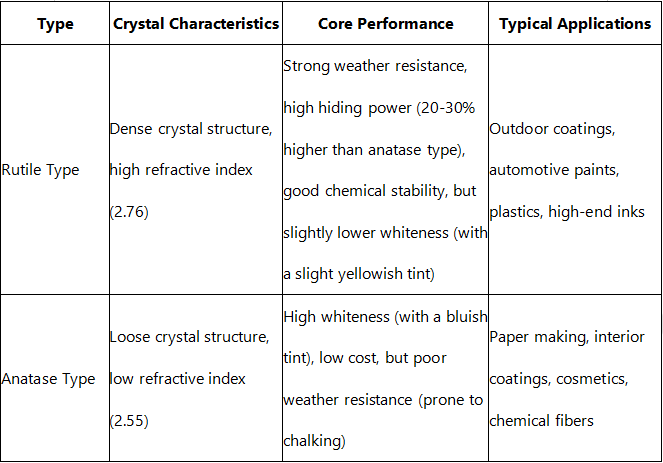

1. Classified by crystal structure

2. Classified by production process

Sulfuric acid method: can produce rutile and rutile types, with lower cost but more impurities, suitable for mid to low end fields (such as papermaking and interior wall coatings).

Chlorination method: Only produces rutile type, with high purity, good dispersibility, and excellent weather resistance. It is mainly used in high-end markets such as automotive paint and MLCC electronic components.

3. Special functional titanium dioxide

Nanoscale titanium dioxide: particle size of 0.01-0.05 μ m, good transparency, used in sunscreen cosmetics, catalysts, and functional ceramics.

Electronic grade titanium dioxide: purity>99.8%, used for MLCC ceramic capacitors (core components for 5G communication and new energy vehicles).