Application areas of alumina powder

2025-11-07

Alumina powder is indeed a "versatile" material in the industrial field. Due to the differences in structural characteristics, various types of alumina powder play a crucial role in numerous fields ranging from basic industries to high-tech materials.

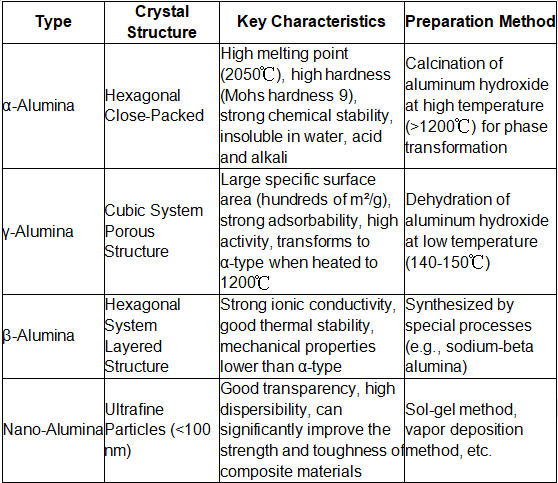

Main types and characteristics of alumina powder.

The core classification of alumina powder is based on its crystal structure and preparation process. Common types and their characteristics are as follows:

1. Special morphological varieties:

Spherical alumina: with good fluidity and high filling density, suitable for electronic packaging materials;

Flake alumina: enhances ceramic toughness and is used for wear-resistant coatings;

High purity alumina (purity>99.9%): high transmittance, used for laser crystals and sapphire substrates.

2. Core application areas and typical uses, different types of alumina powder form differentiated applications in the following fields based on their characteristics:

High temperature and refractory materials

Alpha alumina: As an aggregate for shaping refractory bricks and castables, it enhances the material's corrosion resistance and high-temperature strength, and is used for lining steel and cement kilns;

High purity aluminum oxide: make fused silica crucibles, high temperature resistant boats in semiconductor industry, and withstand high temperatures above 1800 ℃.

In the field of catalysis and adsorption:

Gamma alumina: a desulfurization catalyst carrier and transformer oil deacidification agent in petroleum refining, utilizing its porous structure to selectively adsorb impurities;

Activated alumina balls: for industrial gas drying (such as hydrogen and acetylene) and defluorination of drinking water, with an adsorption capacity of up to 20% of its own weight.

Electronics and Advanced Ceramics:

Nano alumina: added to the ceramic shell of mobile phones to improve wear resistance and drop resistance;

Alpha alumina micro powder: the insulating layer of integrated circuit substrates, with stable dielectric constant and low thermal expansion coefficient.

Functional materials and special products:

In the field of optics, high-purity alpha alumina is used to prepare artificial ruby (laser crystal) and sapphire glass (watch mirror, mobile phone camera protective cover);

Luminescent material: rare earth fluorescent powder carrier, used for LED chips and PDP display screens;

Grinding and polishing: Alpha alumina micro powder is used as sandpaper abrasive for stainless steel mirror polishing and semiconductor wafer cutting.

Emerging application scenarios:

High speed railway braking: spraying high-purity alumina powder onto the railway tracks to increase friction and achieve emergency braking;

3D Printing: Spherical alumina powder is used as a raw material for ceramic 3D printing to produce complex and high-temperature resistant components.