News

What are the characteristics and main uses of graphite anode plates?

Graphite anode plates are used in industries such as electrolytic calcium production and electrolytic magnesium production. It is characterized by low resistivity, high volume density, good bending and erosion resistance, and long service life.

Read MoreApplication scope of zinc oxide

Zinc oxide (ZnO) is an important inorganic material that has a wide range of applications in various fields due to its unique physical and chemical properties. It is widely used in industries such as cosmetics, pharmaceuticals, rubber, and coatings. Zinc oxide can be classified into the followin......

Read MoreApplication scope of expanded graphite powder

Dilated graphite powder is a loose and porous worm like substance made from natural flake graphite, hence also known as graphite worm. Natural flake graphite is a crystal with a layered structure, where carbon atoms in each layer form a network of planar macromolecules through strong covalent bond......

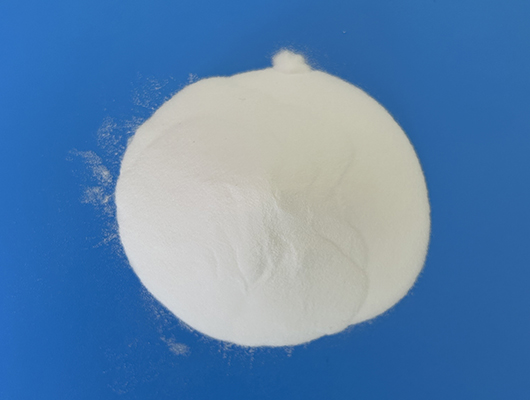

Read MoreClassification of alumina powder

The main component of aluminum oxide powder is alumina, with the chemical formula Al2O32. The purity of alumina powder may vary depending on different applications and manufacturing processes, but generally speaking, higher purity alumina powder can have an alumina content of over 99%. In certain sp......

Read More