Why Is Nano Zinc Oxide Transforming Advanced Materials Across Industries?

2025-11-28

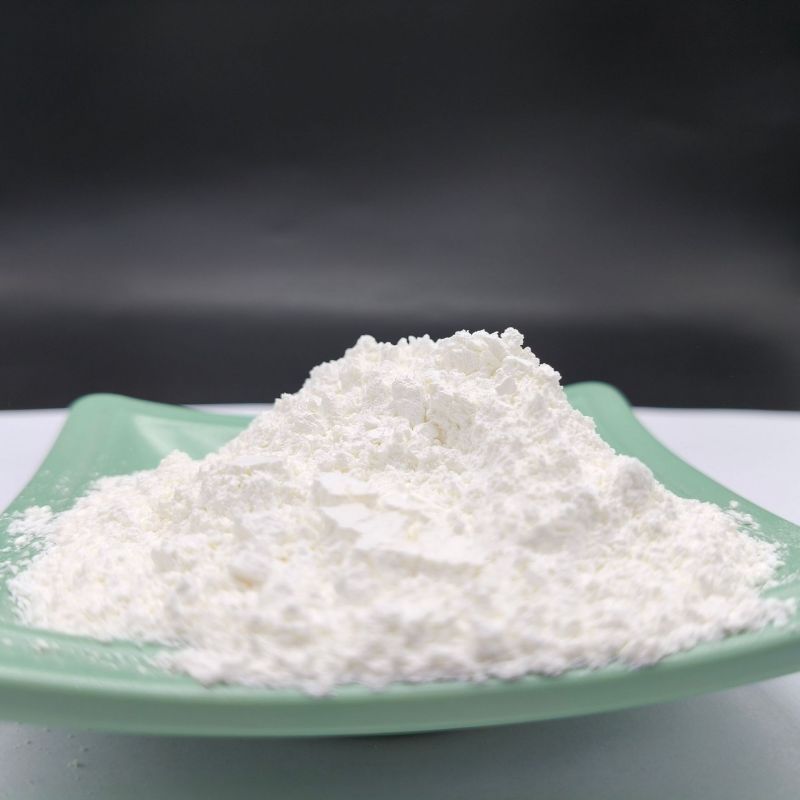

Nano Zinc Oxide (Nano ZnO) refers to zinc oxide engineered into nanoparticles typically ranging from 10–80 nm. At the nanoscale, ZnO exhibits enhanced optical transparency, stronger UV-blocking capacity, higher surface activity, improved antibacterial performance, and superior dispersion stability compared with traditional micron-sized powders. These characteristics make Nano Zinc Oxide increasingly valuable in coatings, plastics, rubber, textiles, cosmetics, electronics, and environmental purification.

What Key Properties Define High-Quality Nano Zinc Oxide?

High-grade Nano ZnO must meet stringent performance benchmarks to ensure consistency in industrial applications. Below is a concise but comprehensive parameter table designed to reflect common global purchasing standards:

Nano Zinc Oxide Technical Parameters

| Parameter | Typical Value | Description / Function |

|---|---|---|

| Particle Size (D50) | 10–50 nm or 20–80 nm | Determines UV-blocking efficiency, transparency, and reactivity |

| Purity | ≥ 99% | High purity reduces impurities and enhances stability |

| Specific Surface Area | 20–60 m²/g | Higher surface area improves catalytic and antibacterial effects |

| ZnO Content | ≥ 97%–99% | Ensures formulation consistency across industries |

| Surface Treatment Options | Stearic acid, Silane, Alumina coating | Enhances compatibility with polymers, oils, water-based systems |

| Appearance | White, loose nanopowder | Indicates good dispersion and low agglomeration |

| Moisture Content | ≤ 0.5% | Ensures shelf stability and smooth incorporation |

| Crystallinity | High | Affects UV absorption, photocatalysis, and mechanical reinforcement |

| UV Absorbance Range | 200–400 nm | Critical for sunscreens, UV coatings, films, plastics |

| Antibacterial Efficiency | 90–99% vs. E. coli / S. aureus | Useful in textiles, coatings, packaging |

These specifications allow buyers to accurately evaluate performance, select proper grades, and optimize downstream formulations.

Why Is Nano Zinc Oxide Gaining Strong Global Adoption?

Industrial demand is rising because Nano ZnO offers several advantages that traditional zinc oxide cannot provide. Below are the core benefits:

1. Superior UV Protection

Nano ZnO absorbs UV-B and reflects UV-A without leaving a white cast, making it ideal for sunscreens, coatings, films, and outdoor materials. Its broad-spectrum UV-shifting capability outperforms most organic UV absorbers in long-term stability.

2. Exceptional Antibacterial Ability

Nanoscale ZnO generates reactive oxygen species (ROS), disrupting microbial membranes. This makes it suitable for hospital-grade textiles, air filters, food packaging, and antimicrobial coatings.

3. High Transparency in Formulations

Unlike larger zinc oxide particles, Nano ZnO offers strong UV blocking while maintaining transparency. This is crucial for cosmetics, clear coatings, and aesthetic materials.

4. Thermal Stability and Chemical Resistance

Nano ZnO enhances heat resistance in rubber, stabilizes plastics under sunlight, and improves weathering resistance in outdoor applications.

5. Catalytic Activity and Environmental Purification

Its photocatalytic properties support VOC removal, air purification coatings, and wastewater treatment.

6. Mechanical Reinforcement in Polymers and Rubber

The nanoparticles improve tensile strength, abrasion resistance, and elasticity across various composite materials.

Together, these advantages explain why Nano Zinc Oxide is becoming a strategic material for performance-oriented industries worldwide.

How Is Nano Zinc Oxide Shaping Future Technologies?

Global research and industrial development are accelerating, driving several emerging trends:

1. High-Transparency UV-Blocking Films

Electronics and packaging sectors increasingly use Nano ZnO in transparent films to enhance outdoor lifespan while maintaining clarity.

2. Low-VOC Antimicrobial Coatings

Green building materials are integrating Nano ZnO for odor removal, mildew prevention, and long-term antimicrobial protection.

3. Next-Generation Sunscreen and Skincare Products

Regulators and consumers are pushing toward mineral-based UV blockers. Nano ZnO is becoming the foundation of future clean-label sunscreen formulations.

4. Photocatalytic Environmental Materials

Self-cleaning paints, air-purifying tiles, catalytic filters, and smog-removing building coatings rely on Nano ZnO’s unique photoreactivity.

5. Flexible Electronics and Sensor Applications

Nano ZnO is playing an increasing role in transparent conductive films, piezoelectric devices, and sensor microstructures.

6. Reinforced Lightweight Composites

Automotive, aviation, and high-performance sports equipment benefit from Nano ZnO’s strength-enhancing effect without added weight.

These trends indicate expanding commercial opportunities and a rapidly increasing need for high-quality, stable Nano ZnO suppliers.

Common Questions About Nano Zinc Oxide

Q1: What is the difference between Nano Zinc Oxide and micron zinc oxide?

A: Nano ZnO has particle sizes in the nanometer range, giving it greater UV absorption, transparency, antibacterial activity, and surface reactivity. Micron-grade ZnO is suitable mainly for rubber and ceramics, while Nano ZnO meets requirements for cosmetics, electronics, high-end coatings, and environmental materials.

Q2: Is Nano Zinc Oxide safe for use in cosmetics and skin-contact applications?

A: When properly coated and dispersed, Nano ZnO is considered safe for topical use according to multiple regulatory evaluations. Its particles sit on the skin surface rather than penetrating deeply. Surface treatments further enhance stability, reduce photocatalytic activity, and ensure minimal irritation in sunscreen and skincare applications.

Why Choose a Trusted Supplier for Nano Zinc Oxide?

Nano Zinc Oxide continues to expand its industrial footprint due to its multifunctional advantages—UV protection, transparency, antibacterial performance, mechanical reinforcement, and catalytic abilities. As global demand rises, choosing a supplier capable of providing stable quality, consistent particle size control, and reliable surface modification becomes increasingly important.

Jiayin specializes in delivering high-purity Nano Zinc Oxide engineered for performance-critical industries. With accurate particle-size control, advanced surface treatment options, and strict quality assurance, Jiayin supports manufacturers seeking dependable, application-ready nanopowders.

To receive customized specifications, technical support, or bulk pricing details, contact us for professional guidance and tailored solutions.